EPS/EPP Recycling

Our EPS/EPP recycling machines are designed to make your recycling of waste material as hassle-free as possible, which means that with the machines from CK Teknik, you can expect minimal dust and noise emittance when in operation.

More information is available about each product and machine in the downloadable PDF.

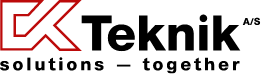

GS10 – Two-step granulator

The two-step granulator is designed to granulate EPS waste for reuse in a molding machine. This is done by manually feeding the waste material into the opening. Once done, the finished granules can be transported by fan and piping.

The machine is equipped with two slow-speed rotors to ensure dustless and comparatively noiseless performance.

GS84 – Granulator

The GS84 granulator is developed for the granulation of polystyrene for reuse in block production.

This is done by feeding the polystyrene either manually or via a silo. Once done, the granulated waste is discharged by an auger at the bottom of the machine, whereupon it can be transported by fan and piping.

The machine is equipped with two slow-speed rotors to ensure dustless and comparatively noiseless performance.

GS85 – EPS granulator

The two-step granulator GS85 is designed for granulating EPS-waste for reuse in a moulding machine.

The waste material is manually fed into the opening.

The finished granules can be transported further by blower and piping.

The GS85 is equipped with two slow-speed rotors to minimize dust development and secure a comparatively noiseless performance.

EPP Pre-breakers

The pre-breaker is designed to break up EPS and EPP waste material.

A solid-welded construction in conjunction with good sound absorption assure stable and quiet operation.

Upon completion, the granules are transported to an outlet at the bottom of the machine via an auger whereupon it is transported by a SM51/52 mill, which breaks up the material into smaller beads and transports it to storage silos.

SM51/52 – Impact mill

The SM51/52 mill is designed to transport and break up the granules from the Pre-breaker/granulator.

The mill breaks up the material to the desired size (5–30mm) and transports it to a storage silo or mixer unit for recycling (BD60).

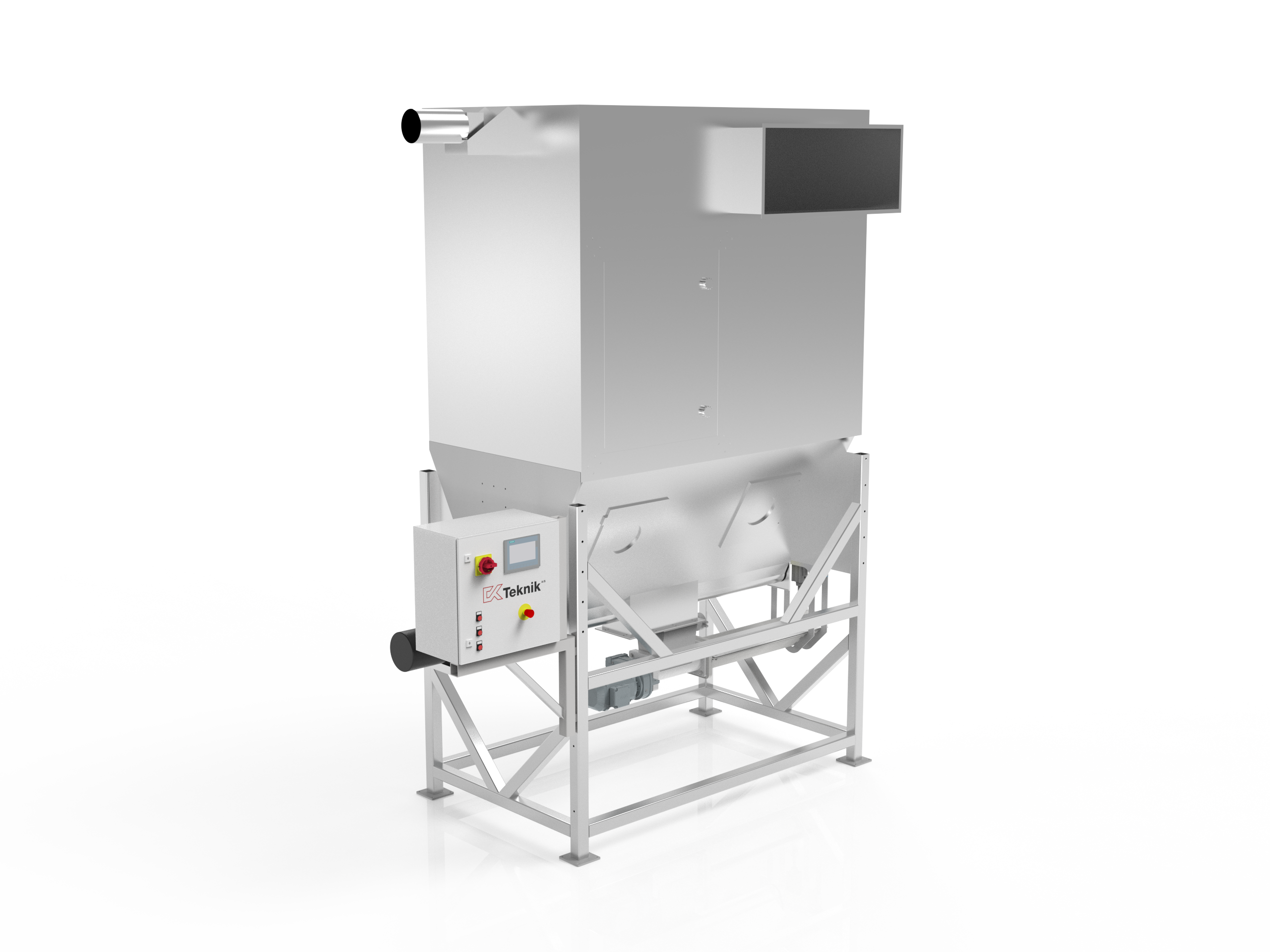

SE24 – Dust separator

The SE24 dust separator with a compactor is designed to remove dust from granulated EPS/EPP waste. For EPS waste, the dust is compacted into blocks, and for EPP waste, it is collected in bags.

The machine is equipped with an integrated blower/separator. On top of that, it comes with automatic filter cleaner.

BD60 – Mixer

The BD60 offers an adjustable mixing and dosing system to mix recycled material and new material and subsequently dose to the mixed material.

The mixer contains 2 antistatic storage silos for recycled material and new material and 2 adjustable star feeders for the exact adjustment of the mixing scale.